Radio-frequency identification, aka RFID, is a far reaching and transformative technology with applications in many business verticals. Be it the education sector, packaging industry, or the travel industry, RFID has simplified and synchronized the entire work process leading to better management of time and resources. Perhaps, taking a cue from these industries, stakeholders in FMCG, automotive, and supply chain management too are experimenting to adopt the technology for better synchronization of their downstream and upstream production processes.

RFID technology: Building bridges, closing gaps in the supply chain management system

Gaps in the supply chain has always been a matter of concern, and yet, for some odd reason these have been accepted as a ‘normal’ situation to be in. Trying to make the most of this ‘opportunity’, major names in the industry like Datalogic, Honeywell International, and Zebra Technologies, have built RFID solutions which can be easily adopted by the retailers as well by automotive OEMs.

Especially in the case of the automotive industry, the issue is not just the gap between the production and distribution processes; but also in the other inbound processes. While the technology is frequently used in the automotive sector to ensure efficient loading and shipping of vehicles throughout the globe, vendors have also come up with chipless RFID solutions that takes this inherent technology a step further.

In case of the retail business, transparency plays a critical role in keeping the sales plan moving and the inventory well-stocked. Alien Technology, a major name in the RFID business, has come up with RFID chips which enables retailers to capture the sales and inventory data for better identification of customer buying patterns while reducing delivery cycle time, and streamlining the supply chain operations. This is a pathbreaking technology that has found massive demand in the American and European markets. Luckily for the vendors, as major names in the retail industry are dipping their toes in the APAC and EMEA regions, the demand for RFID applications for warehouse inventory management has consequently increased in these regions as well.

Blockages in the widespread adoption of RFID applications

Today, even a layman could reel out the basic advantages of adopting RFID applications, however it is only the industry experts who know that the road ahead for this technological innovation is not entirely smooth. Seen as the ultimate solution to the nagging gaps in the supply chain management, RFID solutions have failed to comprehensively impress the target audience as was initially predicted. The lag in its full-fledged adoption has a lot to do with interoperable standardization problems along with legal & patent challenges.

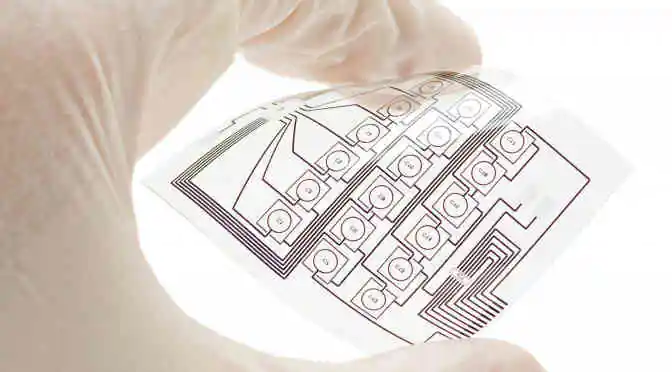

The operational failure rate associated with RFID tags is another major issue which makes large scale adoption of this technology even more difficult. Manufacturers of RFID tags are diligently trying to address this recurring issue by following strict quality assurance guidelines, and pooling in resources to plug in the loopholes in conventional RFID tag designs and feature sets.

While big investments are afoot to innovate foolproof RFID solutions, issues related to patenting are emerging as a more challenging problem to solve. Though expert opinions favor the expected growth of the RFID solutions industry, vendors are yet to find a foolproof solution for issues related with operational automation. And that, could throw a spanner in the works!