Industrial robotics has emerged as a major part of the manufacturing industry. From being programmed easily to adapt to new production lines to producing defect-free products, the use of industrial robotics has gained immense popularity in the US. Unlike manual labor, these robots bring down the chances of product failure drastically. Also, they do not require additional expenditures on insurance, healthcare, etc. which is why they are highly preferred in the US based companies.

Factors behind industrial robots being aggressively adopted

- Until recently the cost of purchasing and installing robots was a major roadblock in its large-scale adoption. But the costs of installing robots have come down drastically. For instance, in the year 2005, the cost to purchase and implement a robotic spot welder was USD 183,000. While in 2014, the price came down to USD 132,000. Industry experts at Technavio expect the price to drop by another 22% by 2025. This explains why there has been such a rise in the adoption of these robots.

- Even the cost of using industrial robots has come down immensely. In a typical computer electronics manufacturing industry, hiring an average worker will cost around $24 per hour; whereas the robot can do the same routine assembly task at $4 per hour. Thus, these robots have emerged as a cost-effective solution for many businesses in the past few years.

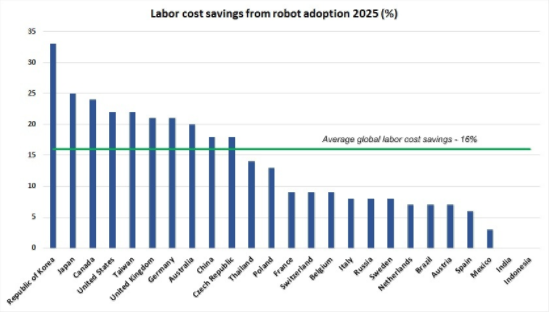

At present, the average labor cost savings achieved by replacing humans with robots in the US is 18%. Our analysts estimate that this figure will increase to 22% by 2020 due to the continuous decline in the cost of industrial robots.

China, Japan, the United States, Korea, and Germany together accounted for 70% of the total industrial robot’s sales in the year 2014. When it comes to robot density, it is Korea, Japan, and Germany which hold the top three positions. The US, in fact, ranks only 7th at the global platform. Also, when compared to South Korea and Japan, the United States does not save as much on its labor charges. Therefore, there is a major drive among vendors in the industrial robot market to launch new products specifically for the US market.

Industrial robots in food and beverage industry

Since 2013, the use of industrial robots in the food and beverage industry has grown manifold. Palletizing and packaging are the primary areas where robots are being used. Of late, industry giants are using robots for grading of fruits and vegetables, handling raw materials, pizza assembly, and in cake decoration.

Thus, it is not just the automotive industry that is moving towards large scale adoption of industrial robots. Apparently, all the major industries throughout the globe are working towards cutting down the size of their labor force by adopting mechanical and robotic substitutes.