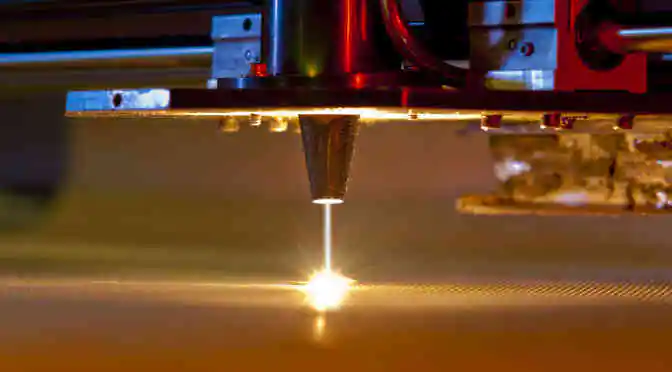

From hand production methods to machines and the rise of smart factory systems, the industrial revolution has pointedly marked the transition to new manufacturing procedures. With the upsurge in demand for metal parts in machinery, especially for the production of automotive components, a number of specialized machinery were introduced to process metal parts including the much favored Special Purpose Machinery (SPMs). These are high-productivity tools that offer vast scope for high-volume production with lower costs when compared to conventional CNC machines.

Applications of special purpose machines

SPM is a combination of sensors, logic controls, limit switches and automatic job clampers that aid in the optimum utilization of man-machine systems. Along with this, they are mainly used in the mass production of small components of two and four wheelers, tractors, trucks, and engines. The major platforms wherein these machines are massively used are at the OEM’s production facilities and machine shops.

OEMs

The original equipment manufacturers (OEMs) including automotive, aerospace and defense sectors are high-end users of special purpose machines. OEMs prefer to undertake complex and important machining operations, such as in-house precision machining which enables them to ensure quality and hence deliver advanced finished products.

Machine shops

Machine shops usually manufacture small and medium sized industrial components that are usually outsourced by OEMs. With the outsourcing of less-complex manufacturing to machine shops, OEMs can direct their focus on the development of new products. Thereby, machine shops adopt special purpose machinery as an important adjutant when manufacturing small components for OEMs.

Driving force : Fabricated metal & government initiatives

As fabricated metals are deployed in several segments including the automotive industry, building products, building machinery, transport machinery and other metal-based hardware, the manufacturing of these metals entail the extreme use of machine tools such as press brakes. Thereby, the rise in the demand for fabricated metals, in turn, fuels the growth for special purpose machines.

In addition to this, governments in several countries are taking major initiatives in terms of promoting the development of the machine tools market. For instance, In Japan, the Ministry of International Trade and Industry has taken the initiative to rationalize the machine tools industry through strategic M&A and disinvestment. The corresponding association coordinates government spending on R&D for machine tools.

Machining it right with Technavio’ s market insights

Despite several benefits and high adoption rate, rapid technological advancements and frequent changes in the global special purpose machine market, as well as consumers’ preferences, constitute significant risk factors for vendors operating in this sphere. Thereby, a reliable source of market information helps in boosting productivity and vendor confidence.

Technavio offers a complete suite of sourcing and market research solutions aimed at helping business decision makers gain profitable insights for better decision making. The advantage can be sourced as a free sample via the link provided herein.